- About Us

- |

- Careers

- |

- Contact Us

- |

- Login Area

- Cement

- Pre-Project Phase

- Project Phase

- Basic Engineering

- Procurement

- Detailed Project Engineering

- Review Engineering

- Project Planning & Monitoring

- Field Services in Construction, Erection & Commissioning

- Equipment Inspection

- Mine Scheduling & Optimization

- Market Entry & Distribution Planning

- Management Information System

- Manpower Planning & Human Resource Systems

- Operations Phase

- Power

- Highways & Bridges

- Engineering Support & Detailing

- Cement

- Pre-Project Phase

- Project Phase

- Basic Engineering

- Procurement

- Detailed Project Engineering

- Review Engineering

- Project Planning & Monitoring

- Field Services in Construction, Erection & Commissioning

- Equipment Inspection

- Mine Scheduling & Optimization

- Market Entry & Distribution Planning

- Management Information System

- Manpower Planning & Human Resource Systems

- Operations Phase

- Power

- Highways & Bridges

- Engineering Support & Detailing

Introduction:

Holtec possesses the necessary experience, know-how, technical skills and manpower to execute the services for Plant Operations & Management, adhering to the required quality standards. All unit operation and maintenance can be taken up from limestone receipt to cement dispatches.

Coverage:

During dry run and commissioning, we can ensure that the plant is smoothly test operated to the best of its potential. We can also help in identifying any problems and/or inadequacies in the plant, enabling the owner to get the same rectified by the Suppliers.

During Plant operation phase, we can ensure that the quality, quantity and consumption figures provided and obtained during the commissioning/ performance guarantee tests are met on continuous basis. Holtec focuses its efforts to continuously improve the sustainable performance. We also ensure that the plant and equipment are well maintained, free from defects or any malfunctions and are in good condition.

Responsibilities include:

- Planning and scheduling of operation maintenance and quality control.

- Preparing operating and maintenance procedures, based on the guidelines and instructions provided by the equipment suppliers, to cover :

- Emergency procedures.

- Safety regulations and work permit systems.

- Condition based monitoring systems and controls for critical plant equipments.

- Critical and strategic spare parts stock and replenishment system.

- Ensuring smooth economic and efficient operation of the plant in a professional manner.

- Controlling dust emission and emission of other pollutants within the agreed design limits.

- Preparing and submitting reports for information on plant operations and maintenance.

- Implementation of adequate, appropriate and suitable management control system for necessary decision making at various levels for material control, human resources planning and administration, budgeting, safety and security policy etc.

- Providing the services of an off-site expert team to promptly provide any advice/ guidance as may be needed for any other services including marketing, logistics and financial management.

Methodology:

Plant Operation and Management is taken up in two phases:

Phase I: Dry Run, Commissioning and Taking Over

This is a period when the Project Execution Agency/ Agencies for the project is/ are in last phase of finishing their responsibilities and responsibility of plant operations and management needs to be taken over by the owner. This phase generally commences with dry run of the plant equipments and shall continue till the Provisional Acceptance. We can provide the necessary technical skills and experienced work force according to the progress of work and according to the organization structure.

Phase II: Operation, Maintenance and Management of the Plant

This phase commences after the Provisional Acceptance. We can provide the required technical personnel for operation, maintenance and management of the plant withsupport personnel from owner. We can also take the complete responsibility of plant management, operation and maintenance.

Benefits:

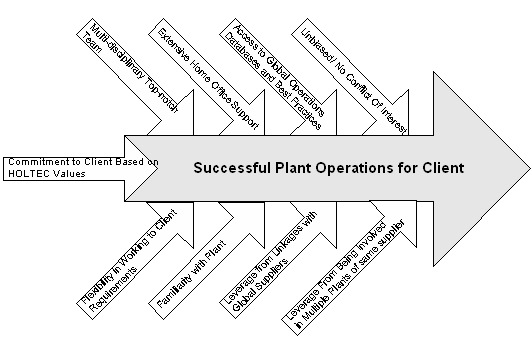

Holtec possesses all the required skills and qualities for successful operation and management of the plant.

- With substantial experience of performance enhancement, our goal is to enhance productivity of the plant and not to simply do operation and maintenance.

- We have a continuous source of feedback on the performance and operations related aspects of all the renowned cement manufacturers and suppliers worldwide.

- We have good relations with almost all the equipment suppliers worldwide and are in a position to use our influence for spares procurement.

- We have large databases for benchmarking plant operations and follow best practices prevalent in the industry.